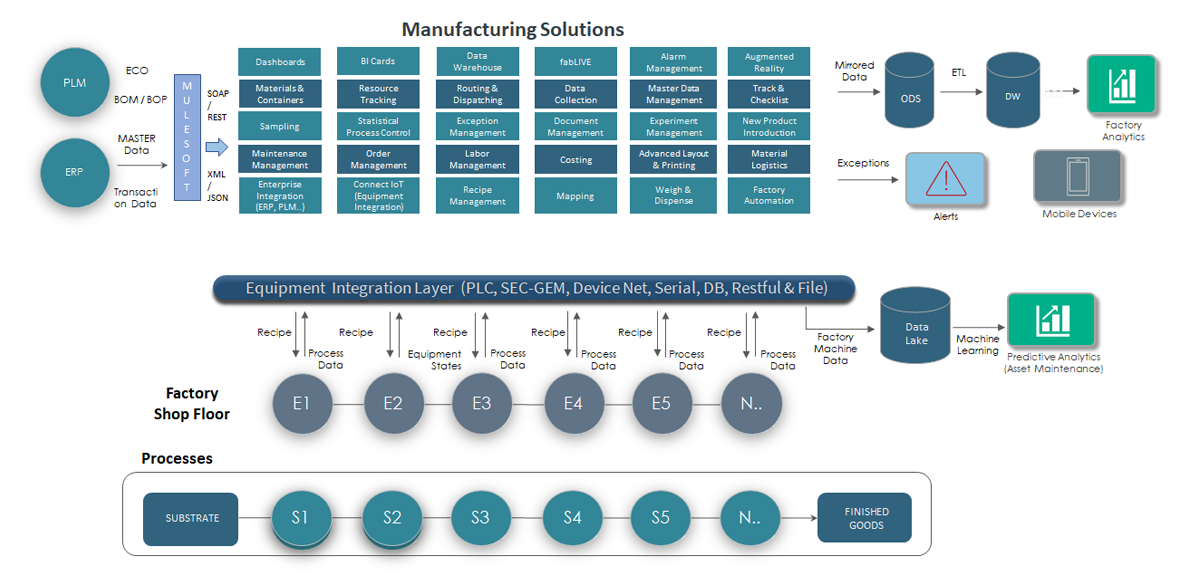

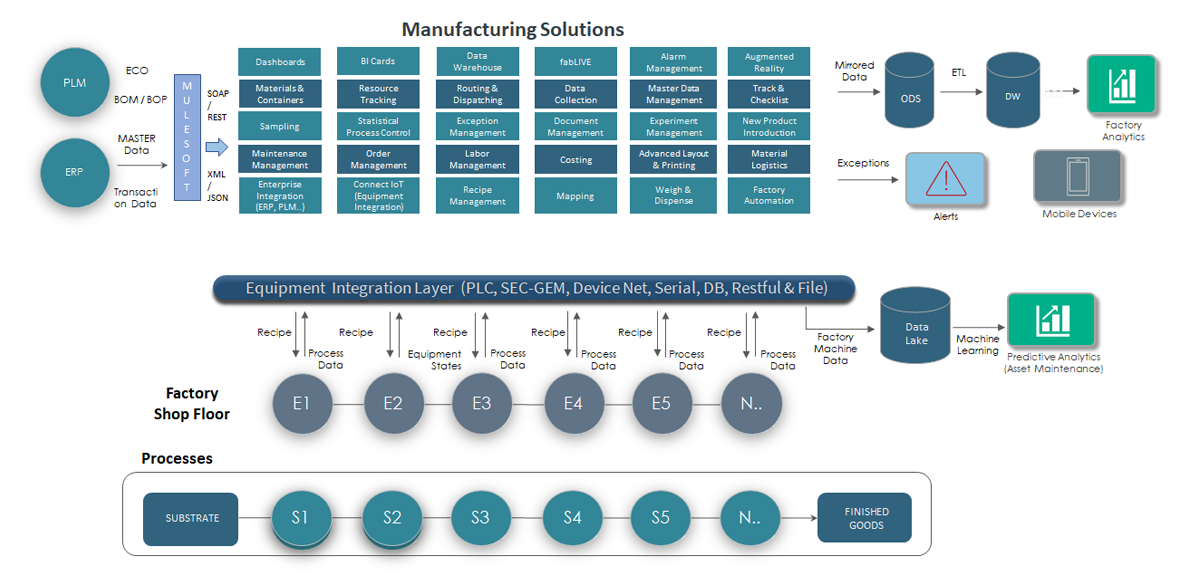

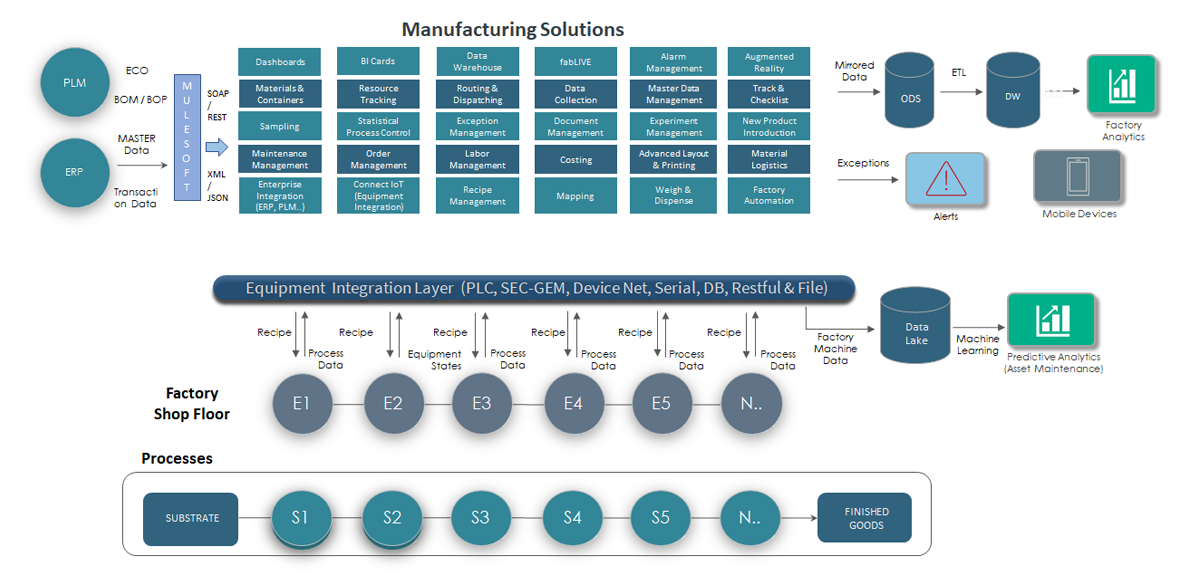

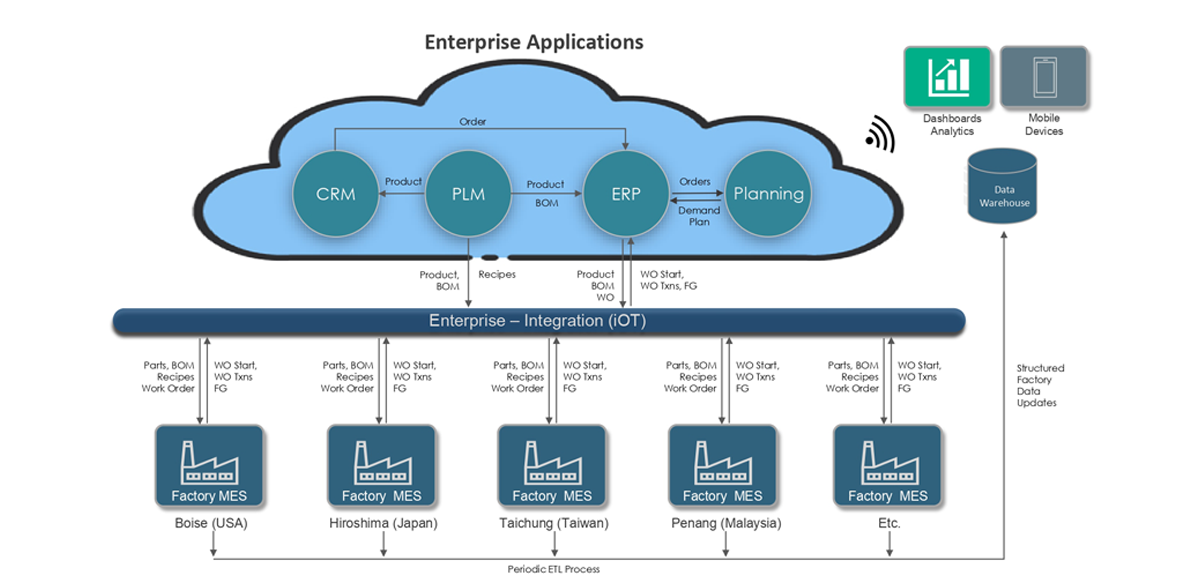

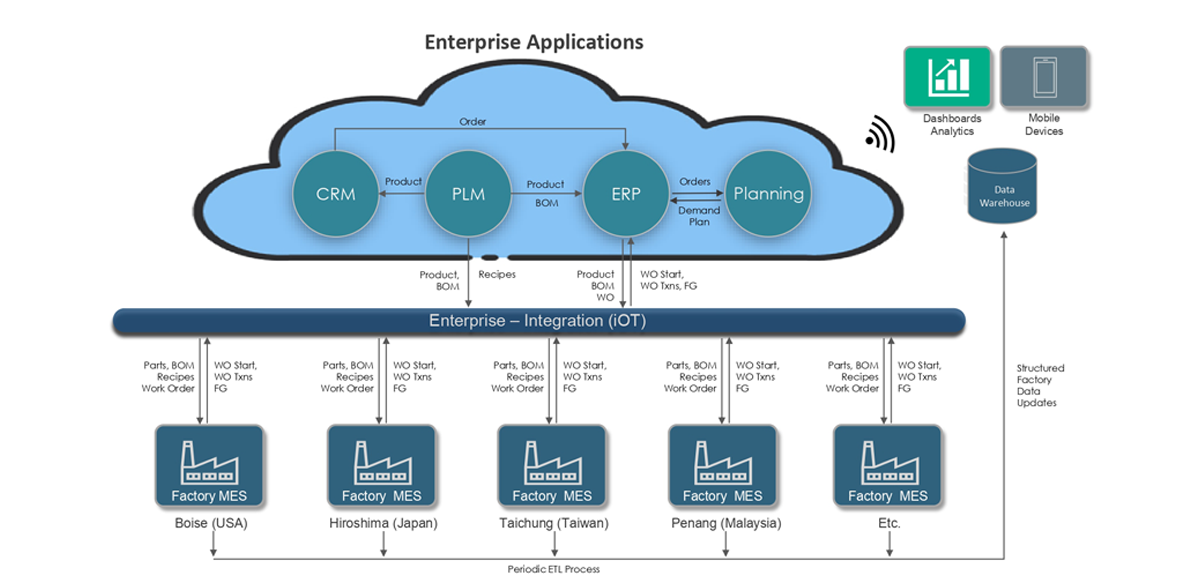

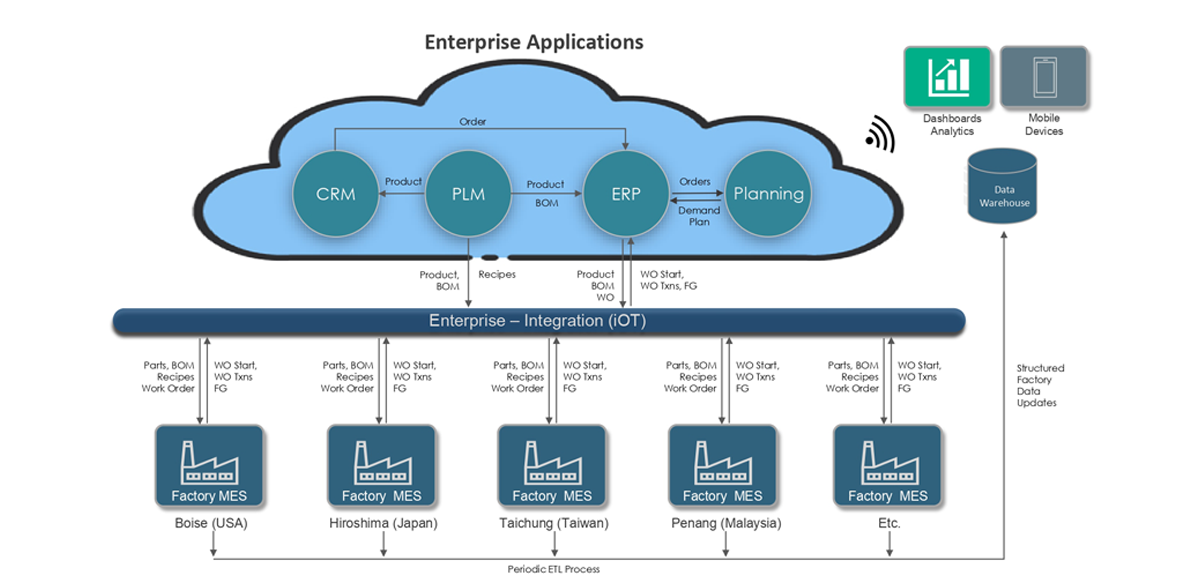

Critical Manufacturing is a complete, modular MES to accommodate the needs of complex discrete industries. The system has long supported the industrial internet of things (IIoT), mobile devices, automation, sensors, etc. With revolutionary technologies such as an IoT data platform, factory automation, augmented reality, and a factory digital twin, focus on leveraging the data that matters and confidently progress towards Industry 4.0.

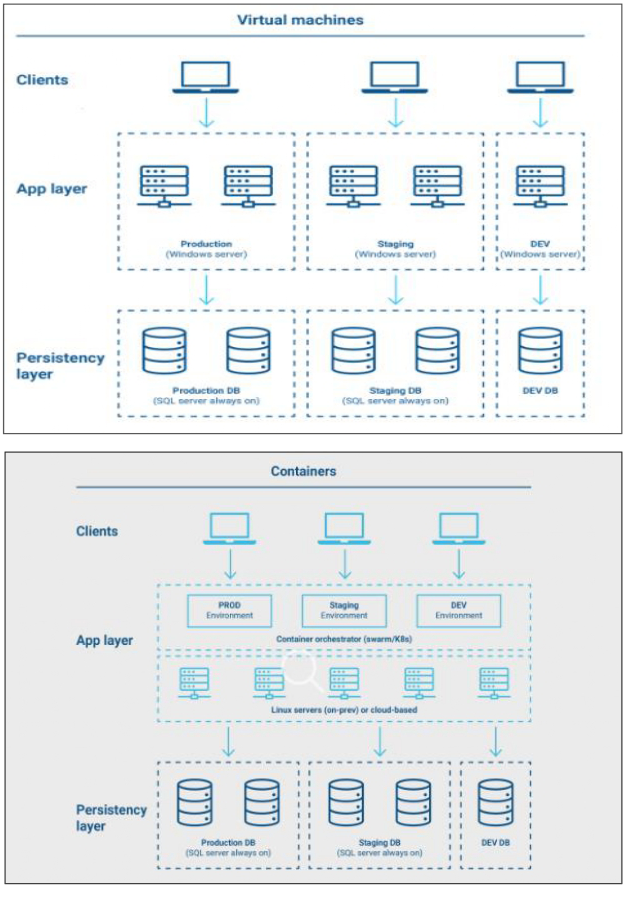

Critical Manufacturing MES is focused mainly on discrete manufacturing, with clients in the semiconductor, electronics, repetitive flow/batch and medical device industries. It is continuously expanding its partner and SI ecosystem. Focusing on simplifying deployments and upgrades in multiple environments, including Microsoft Azure.

|

Batch, Lot & Unit Tracking | Traceability & Genealogy | Routing and Dispatching | Data Collection & Acquistion | Operator Training & Certification |

|

|

|---|---|---|---|---|---|---|---|

| Consumables Management | Tooling Management | Work Instruction / SOPs | Label & Document Printing | Task Management | Order Management | ||

|

NPI | Recipe Management | Experiment Management | ||||

|

Equipement Tracking | Maintenance Management | Calibration | ||||

|

Statistical Process Control (SPC) | Corrective & Preventive Action (CAPA) | Non-Conformance Reporting & Dispositions | Sampling Based Inspection / AQL | Document Management | Electronic Signatures | |

|

Advanced Planning & Scheduling | Materials Management | Costing | ||||

|

Dashboards | Reporting and Analytics | Operational Data Store & Data Warehouse | Alarm Management | Factory Digital Twin | Augumented Reality | |

|

Equipement Integration | Factory Automation Workflow Management | Enterprise Integration (ERP, PLM, ...) | ||||