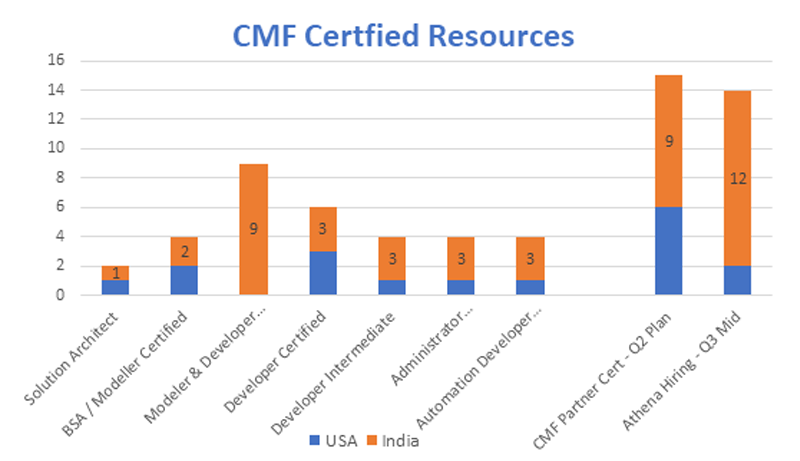

Athena team has various certified functional roles like Modeler, Administrator, Front-End Developer, Back-End Developer, and Automation Developer that are required to implement Critical Manufacturing MES

Currently, our team is working in association with CM project team in implementing CM MES for various clients across domains. Athena members are Involved in requirement gathering, modeling, module customization, system integration & testing.

Athena has CM Product Experiences in v7.2, 8.x & 9.0 Implementations and Post Go live Support. We have around 50+ CM MES Trained.

TDK Electronics develops, manufactures, and markets electronic components and systems, focusing on fast-growing leading-edge technology markets. Project involved with Enterprise Integration has been implemented for real time synchronization of the data between SAP and CMF. Connect IoT / Equipment integration is implemented using OPC-UA protocols and features achieved for automatic data collection, send/receive event, commands between MES and Equipment to process the data from/to equipment. Service customization, Developing Automatic Test utility, change state features, recipe validation, OEE real time dashboard and custom driver API implementation.

Alfa Laval deals in the production of specialized products and solutions for heavy industry. Project involved with ERP Integration for Production order, Dynamic Production Route, Customized Material Views to provide all necessary details of materials, navigations to various functionalities. Simple and Group Track Out functionalities were developed for operators to perform necessary transactions based on the various configurations. Automatic Label Printing to Auto select Printing Labels from the context tables during different operations. The new Situation Dashboard developed will provide a full view of Production orders/materials details.

Lumentum delivers innovative photonics to accelerate the speed and scale of cloud, networking, advanced manufacturing, and 3D sensing applications. CM MES implementation involved with Modeling, Integration (AWS, Equipment, ERP, PLM, LMS & TDS), Design, Development, Rollout, Testing, and Reporting. Key CM MES Modules include WIP Track-IN, Document Management, Maintenance Management, Labor Management, SPC and ERP Integration.

Athena CoE team has developed customized GUI Component (Shop Floor View, Material Start, Material processing, Substrate information). Custom Services, DEE, Name Generator and Queries will accelerate the project development.

ams OSRAM is a global leader in intelligent sensors and emitters. Project involved are Synchronize the data collected in MES with the customers inhouse applications using TIBCO EMS, Real time synchronization with SAP on the Raw material consumption, Scheduled the transport job in CMF with the data provided from INFICON (External scheduling system).