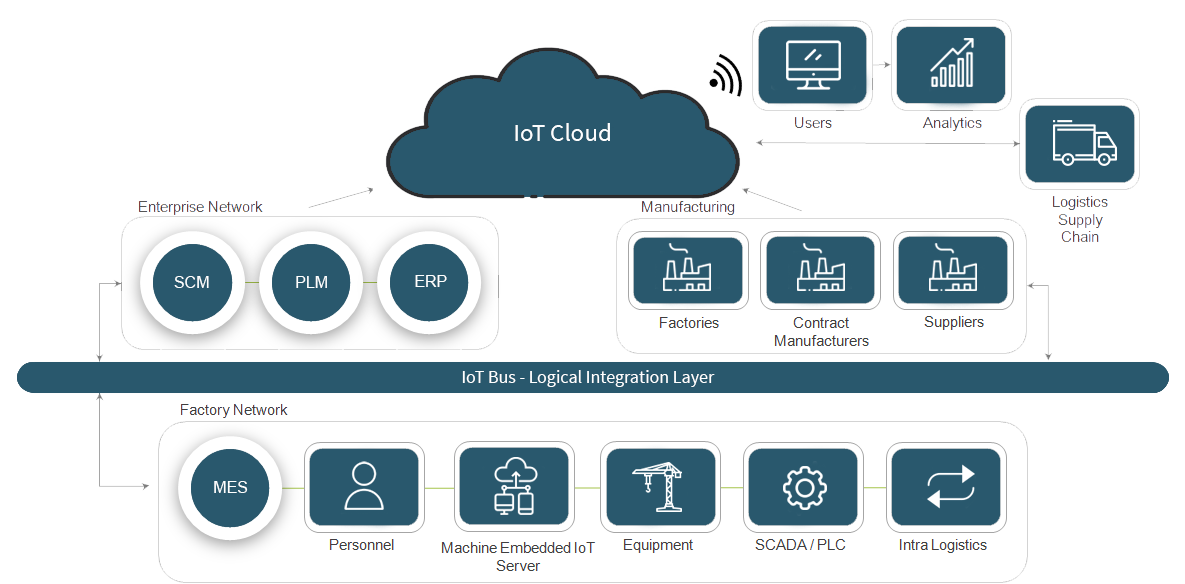

Athena focuses on delivering advanced Industry 4.0 Digital transformation solutions that power smart factories. Our core competences in Manufacturing Execution Systems and extensive experience in connected factory and automation solutions has enabled its customers to optimize their manufacturing processes and supply chains resulting in improved product quality, cost and on-time-delivery.

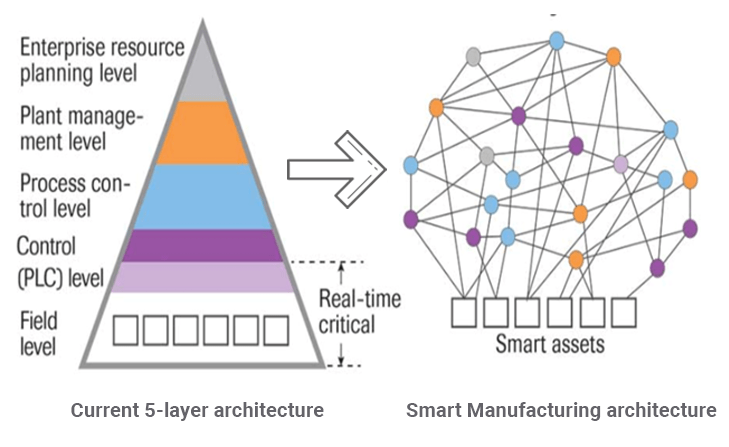

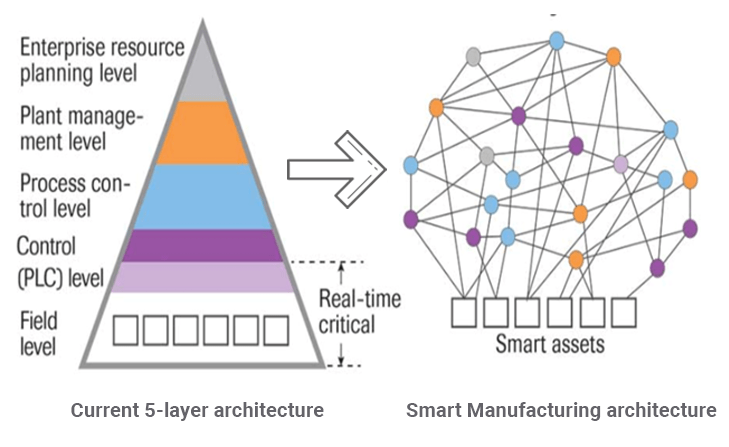

A smart factory is flexible, can self-optimize performance across a broader network, self-adapt to and learn from new conditions in real- or near real-time, and autonomously run entire production processes.

The Smart Factory achieves direct KPI benefits that result in Higher Yield, Product Quality and Good-Out’s, while lowering Cycle Times and overall Production Costs.

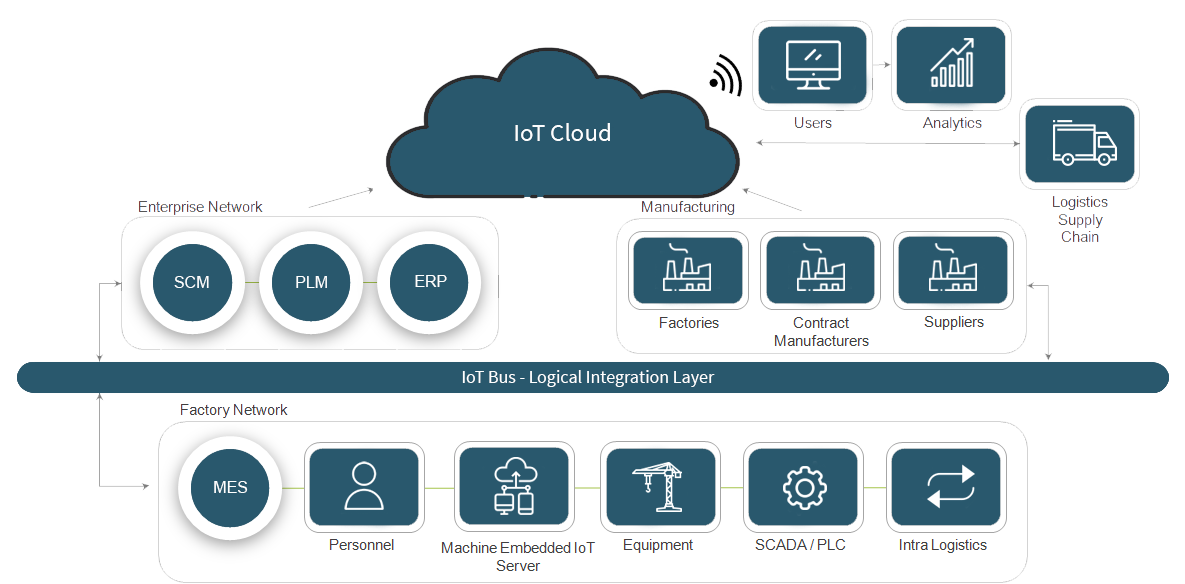

This is accomplished by integrating technologies along the Production Life Cycle, to continuously improve, Production performance, automation, control and critical Insights.

Smart Factory Analytics provide ‘Continuous Cycles of Learning’, native within The Smart Factory, where integration and data collection are essential building blocks.